X chooses to defy hydrosport conventions in every way that we can. In our quest to build a better hydro power redirection systems, we refuse to accept any pre-existing market attempts as an “industry standard”, pushing to come up with new and superior solutions. The search for more efficient power handling has led us to the new awesome Dual 180 for the summer of 2016. Power, efficiency, and control, are the characteristics of the new Dual 180 hydro channel system from X-Jets. Also nicknamed the “Shotgun U” due to its double barreled construction, this unique configuration handles 300+ horsepower and thousands of liters of water moving at 70+ miles and hour. Certainly not a lightweight task and the X Hydro Channel is a heavyweight solution that sets the new standard on power redirection.

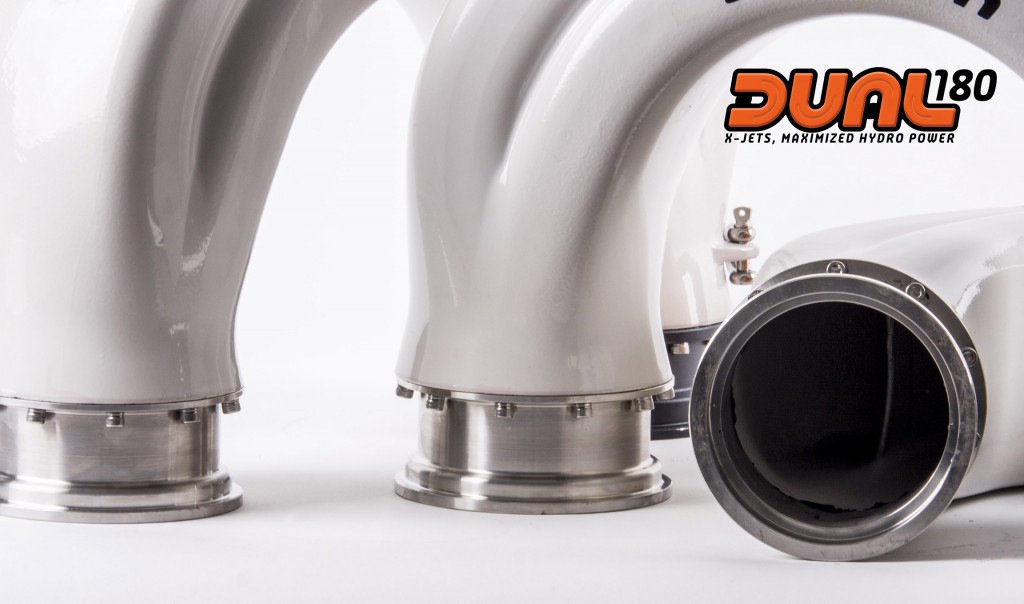

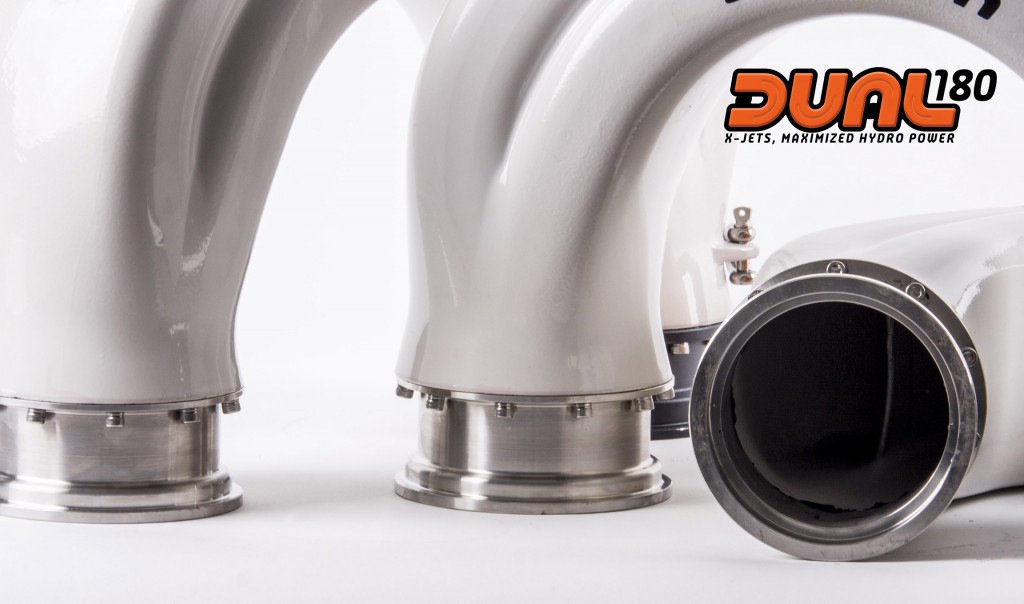

So many of the hydro products on the market look like unfinished plumbing projects, (or direct copies of unfinished plumbing projects) not X. We care as much about how we build it as how we make it work better. Beautiful 3D surface construction gave us the results in our hydro testing and give the Dual 180 the beauty it rocks on the outside. We are specialized in in-house 3D modelling and use surface modelling software to achieve the hydrodynamic surfaces that set us apart and ahead of our competition. Check our competitors websites, most never show a photo of their “U” hydro redirection system, it is the seemingly forgotten utilitarian element that gets little attention or detail. X makes sure that all aspects of your hydroflight system look as good as they perform, all the while building systems that last longer than anything else on the market. Its the attention to detail that we strive for in everything we do.

Dual 180’s are high temperature powder coated, gravity cast, marine alloy aluminum. Powder coating is inside and out so that the inside walls have the least amount possible of power loss due to wall friction. Our mounting flanges are a level of detail to themselves. Full stainless 316 on the water entry side where the Dual 180 attaches to the X-Venturi.

We engineer our U “re-direct” with careful attention to hydro dynamics and smooth powerful water transfer. This unique “U” divides the water flow into two vertically shaped channels and rips the water around the corner in two “ribbons”, limiting spiraling and then recombining the two streams into one powerful mass of water moving through the 20 meters hose. This is the power that took Ben Merrell to first place at the recent Hydro Fest, and powered Mike Helton and Hunter Verlander in Japan. The first time Ben rode the Dual 180, he got out of the water and said, “There is so much power, I’m shaking with adrenaline!”.

How did X build the next generation of hydro power handling systems that adapt and channel the power of the jet ski to the hydrojet device? Water is a slippery beast, asking it to turn a 180 degree corner and maintain power and integrity is something hydro engineers grapple with. Far from being a homogeneous mass traveling through a hallway or tube, water twists around on itself and spirals in 3D. Changing the outside shape of the channel is one thing, however the core of the water still twists and spirals as it powers through the turn. One established methods of controlling fluid power robbing turbulence is to insert vanes or flow directors into the stream. From wind tunnels to jet ski pumps. We began with building 3D models and testing them in special water flow analysis software. One of X’s strengths is modelling smooth surfaces and transitions we built models, we tested and we rebuilt. Exploring different options and different methods of channeling the water. After almost 30 generations of testing, we had the results we were looking for, now time for real world testing. We used computer controlled milling machines, aka CNC, to cut large aluminum blocks into the exact shapes of the computer files. Two halves welded together and the billet cut CNC flanges attached. Testing took place in China, Japan Florida, Texas and ultimately Nevada where Ben Merrell took his Dual 180 powered Yamaha to the first place on top of the podium at the recent Hydro Fest event sponsored by Jetpack America. X pulled the trigger and started full production. Production units are arriving the third week of June and begin shipping to customers.

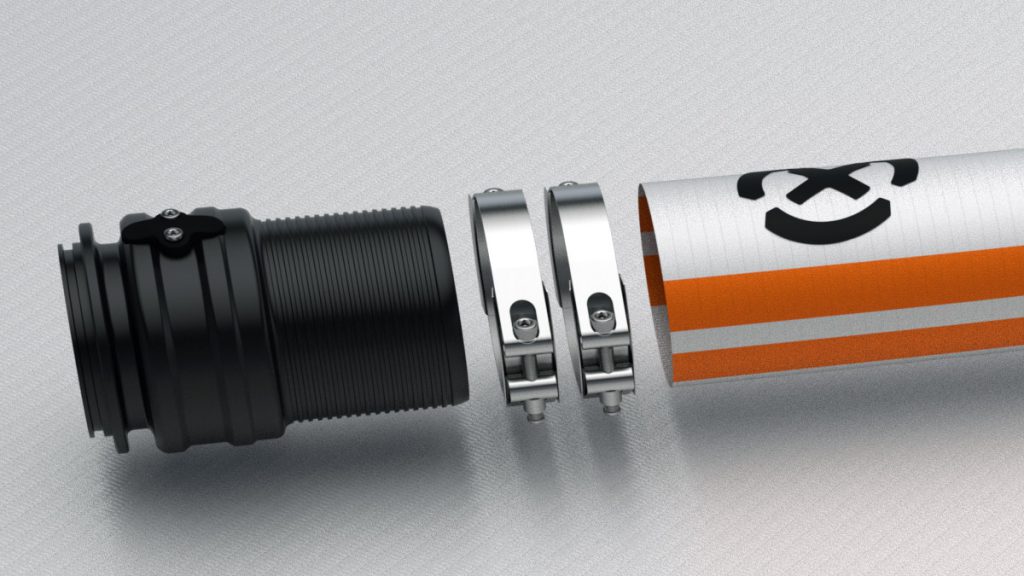

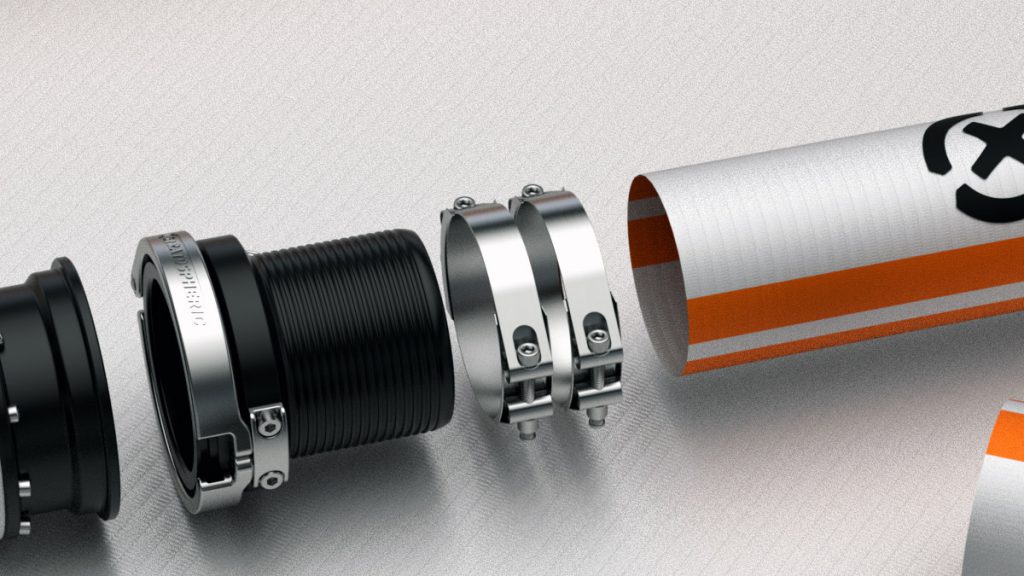

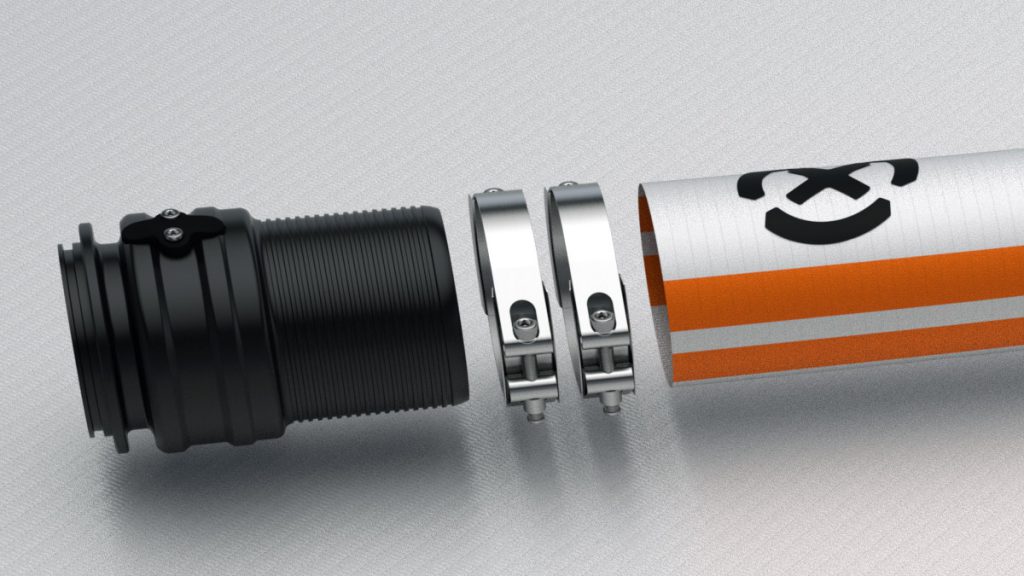

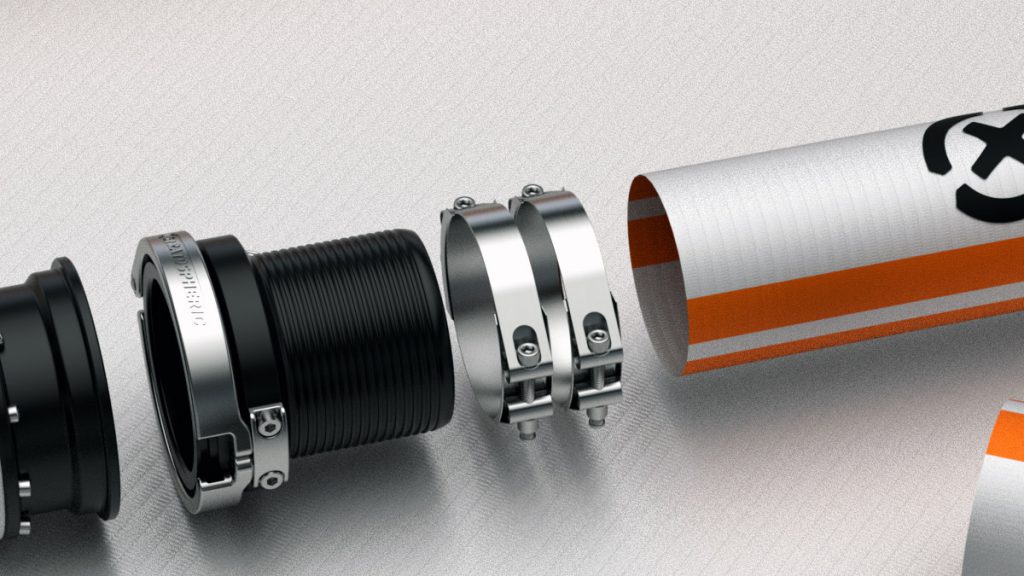

How it works: The thrust of the JetSki/PWC is redirected 180 degrees from the rear facing impeller pump towards the front of the JetSki, from there the Jetpack, or the Jetblade, directs the thrust by rider steering. This means that all of the available power from the PWC pump is available to the rider with none of the weight. This “tether” is the essence of what makes a hydro sport device fly, and pulls the jet ski along for the ride. There have been various attempts from other companies at guiding this force, Stratospheric knew we had to do better. The goals: more smooth water flow, less cavitation, more resilience, better mounting, stronger materials, no small parts to break or get lost, simple breakdown at the end of the day. These three component sets pictured above form the X-Hydro Channel, Venturi, 180 redirect, and LeMans hose with CNC couplings. A venturi adapter, one per brand of jet ski, Yamaha, SeaDoo and Kawasaki make installation direct and shim-free. Four bolts and ready to go. One brand choice of venturi is always included and not an additional hidden expense. We wanted to compliment the power of the PWC pump, not break it, so we introduced the first flexible re-direct in the business, we now have been flattered by several of our competitors adopting the same solution. Less broken jet ski pump housings are a good thing for the whole industry.

Our hose is the best in the business, the “LeMans” named after the famed 24 hour race in France, we wanted an enduring hose with smooth power transfer. Dual laminated polyester sandwich, PU thermoplastic, high pressure bonded to our exacting standards. Tested by the manufacturer and by us in house for adhesion and tensile strength. This is not a lightweight hose that was not prepared to meet the real world demands of the sport. This is hose that was built as tough as possible from the get go.

Hydroflight and hydrosport power system for conversion of a personal watercraft, aka jet ski, into a water thrust powered flight platform. The most technically advanced water thrust system in the sport. X offers several different configuration to meet your performance needs.

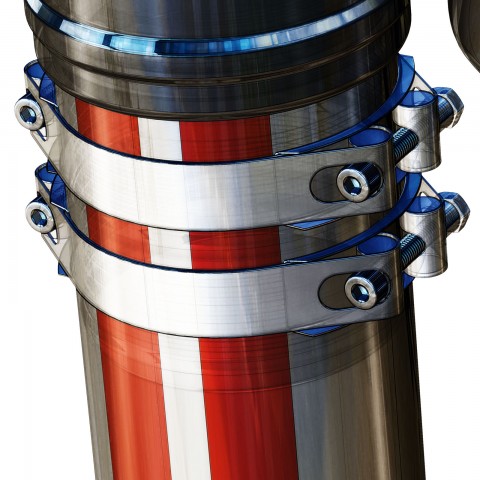

CNC Machined fittings, 316 stainless steel clamps, “W5” not the cheaper “W4”

Do we need to mention that all of the materials are marine grade and can stand up to salt water? Naturally, that is the way we roll, we build it right because we know it is going to get used hard, everything heavy duty from clamps to hose to dual layer reinforced silicon rubber. Add in the X standards of hard anodized aluminum, 316 stainless steel, ultra tough but flexible webbing expansion wraps, you have a power system that turns 300 horsepower around and put it under your flying control.

Have another flight solution from one of our competitors but looking for a better power channel? X-Jets X Hydro Channel makes them all perform better. Contact us today for details.